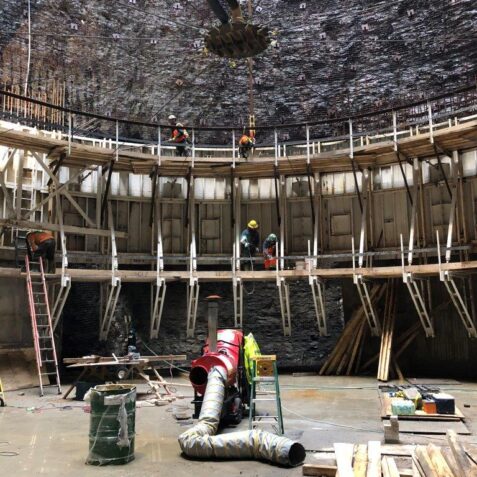

ACCESS &MINING SHAFTS

FASTER & VERSATILE

Shafts are an essential part of the support and supply system for the work flow underground.

Vent shafts will guide an adequate supply of fresh air while access and equipment shafts provide an adequate supply of men and material. Whether concreting from the bottom up or from the top down, EVEREST shaft forms can be an important part of your time and cost cutting operation.

They will provide concrete permanence and stability to newly excavated shaft walls.

CUSTOM BUILT – FIXED GEOMETRY

We design a work environment custom to addresses all your needs as it is custom built. It’s faster, so it’s even more economic as you save on time and labor in the long run.

When concreting up from the bottom, EVEREST custom shaft forms are moved from one pour to another as it extends your shaft lining up to the top.

Once the key panel is pulled free from the wall, the form is stripped and raised to the next pour level.

EVEREST hanging work platforms can he lowered right onto the center of the form to give your men direct access to the formwork.

SAFETY GOES FIRST

They are manufactured with a maximum of safety and workability.

As in the mining industry where blasting, mucking and lining work must be carried on simultaneously from the top down, EVEREST can provide you with our dependable blast proof forms.

On all vertical linings, EVEREST formwork and equipment will help you meet your deadlines SAFELY and ECONOMICALLY.

A Strong & Reliable Partner

What our clients say

Everest supplied a custom formwork system and rebar gantry for a complex large diameter tunnel. In the design phase, Everest was able to provide innovative solutions and incorporate our ideas into their systems, ultimately saving cost and schedule on our project. Everest provided great engineering support along with on-site assistance as we used their systems during construction. The equipment performed very well and provided a product that very pleased the Owner. Everest stands behind their work and products and we look forward to using their systems on future projects.

- Casey Henning, project engineer at Atkinson Construction

Having used Everest’s custom steel formwork for two of the major tunnel infrastructure projects I’ve been involved with in North America, I’ve come to expect thorough and robust design, careful consideration of cyclability, and quality fabrication. They have earned their place at the top of my list of preferred steel formwork suppliers.

- Darren Von Platen, Project Manager at Traylor Bros.

Michels Corporation has nothing but great things to say about Everest Form Carrier experience on this project. Everything from time of quote/ engineering, procurement, delivery, service and product, we had zero issues from start to finish with your product. We were very satisfied and met our production rates each and every week on the project.

- Matt Gassner, Field Operations Supervisor at MICHELS Corporation

More than 10 years of experience with Everest tells me that this is a trustable formwork company! Everest designs what contractors need, builds products that last, and services customers who are always satisfied. We are keeping Everest on our side to make us more successful!

- Ran Chen, project engineer at J.F. Shea Construction

We needed some custom shaft forms built in a short time frame. We quoted these forms out to other vendors but no one was able to meet our deadline. Everest took on the challenge and delivered before the forms were needed. Their staff is great to work with and they do incredible work for a reasonable price. If you are in the market for standard or custom concrete forms, I would definitely not look past Everest.

- Eric Friederich, Equipment Manager at Frontier-Kemper Constructors